The Traditional Hard Candy Made With Leftover Barley Water

Located in an old mill house on an island in the Loing River off of Rue du Pont in the town of Moret-sur-Loing, just south of Paris, France is the Musee du Sucre d'Ogre: the Barley Sugar Museum. The town has been producing these popular hard candies without any artificial coloring or flavorings of any kind since the 17th century. A favorite of religious orders, royalty, philosophers, and actors alike, barley sugar candies have passed through the annals of history to become a favorite across the European continent, and even into Asia.

France has a long history with the sugary side of barley. The famously almond and floral flavored orgeat syrup was originally a simple barley syrup concoction. Barley has also been famously used in some types of whiskey and beer, bringing the toasted, woody flavors we've come to associate with those drinks. As barley is a grain and a carbohydrate, it contains a certain amount of sugar, which can be extracted using various methods.

Barley sugar hard candies are partly a byproduct of soaking barley in water. The water would be put to use in making the hard candies, while also providing the sweets with the amber color they have become known for. They tradition treat has been a favorite for hundreds of years.

The beginings of barely sugar

While there is no documented evidence that confirms exactly when and where barley sugar was first produced, there is a consensus that it began in either England or France. The Musee du Sucre d'Ogre explains that its own heritage dates back to the 17th century. During King Louis XIII's time on the throne, the Benedictine nuns of Moret-sur-Loing began using barley water and cane sugar to create syrup that they then turned into candies. Enjoyed by the French during the monarchy, the revolution, and well into Napoleon's imperial ambitions. The Sisters prepared their candies all the way into the 1970s when they passed on their closely guarded recipe to the town confectioner.

The name barley sugar may have come about through a misunderstanding between France and England. The French for "burnt sugar" is sucre brûlé, which the English mistranslated as "barley sugar." The English phrase was then retranslated back into French, becoming sucre d'ogre. The name stuck, despite the actual grain having very little to do with the candies themselves.

Barley sugar candy's popularity extended well beyond France. Across the channel in England, the Victorians were very fond of extravagantly molded barley sugar candies as a Christmastime treat. The famous actress Sarah Bernhardt refused to go on stage without first warming up her throat with a barley candy lozenge. The soothing properties helped her voice, just as it had the priests on whom the Benedictine sisters first tested their candies.

How barley sugar is made

Barley plays an overall minimal yet important role in the candy-making process. You need barley to get the key ingredient: barley water. The grain is soaked in water, brought to a boil, and left to simmer for several hours. The barley water is then allowed to cool before being strained and separated from the greater grain. It's at this point that the sugar is added.

When making syrups, particularly one intended to produce a hard candy, the ratio of water to sugar needs to tilt towards the sugary end. In this case, there should be a two-to-one sugar-to-water ratio. The mixture is then boiled down to a point where the majority of the water has evaporated and only syrup remains.

At this stage, it is important to keep an eye on the syrup's temperature. Confectioners look for the hard crack stage, which is between 300 to 310 degrees Fahrenheit. Once the syrup has reached this temperature, the cooking pan is removed from the heat and plunged into an ice bath to prevent the syrup from overheating. After a brief chilling period, the syrup is ready to be turned out onto a cool work surface, such as marble, and cooled to the point where it is just malleable enough to shape into twists or lozenges. Victorian-era confectioners used to design extravagant molds with which to make barley sugar candy toys to great effect.

Barley sugar vs barley sugar candy

There are two different types of confections one can make from barley water: barley sugar and barley sugar candy. The difference between the two is minimal at best. However, when it comes to candy making, the simple addition or exclusion of a single ingredient can change the nature of the confection completely. Such is the case when it comes to methods of making barley sugar and barley sugar candies.

Cream of tartar, which is a substance extracted from the bottom of empty wine barrels, is often used in candy-making as a stabilizing agent. What it does is keeps the sugars from over-crystalizing. Sugar crystals have a tendency to bind to one another as they are reforming during the cooling process. What can sometimes occur is that the sugars will clump together and form an uneven mass in the candy. So, instead of clumping to each other, the sugar crystals will seek out the cream of tartar and attach themselves to that. This creates a balanced, even consistency and provides the candy with additional strength, which comes in handy when shaping. Cream of tartar is commonly added to barley sugar for exactly this purpose.

Barley sugar candy leaves out the cream of tartar in favor of corn syrup, which keeps the candy from both getting cloudy and melting. The additional stability the corn syrup adds allows for other flavors to be added without adversely affecting the consistency of the candy.

Brands to consider

While barley sugar candy is one of the longest-lasting candy traditions, it can be rather tricky to find. Over in France, there are the famous confectioners of Moret-sur-Loing, who have been producing the same barley sugar candies for centuries. Officially branded as Sucre d'Orge de Religieuses de Moret, these amber-colored confections are sold as either the traditional twisted sticks or as candy drops delightful packaged in nouveau containers. You may have to travel all the way to Moret-sur-Loing to purchase some. If you're already a barley sugar lover, perhaps this won't be much of an imposition for you.

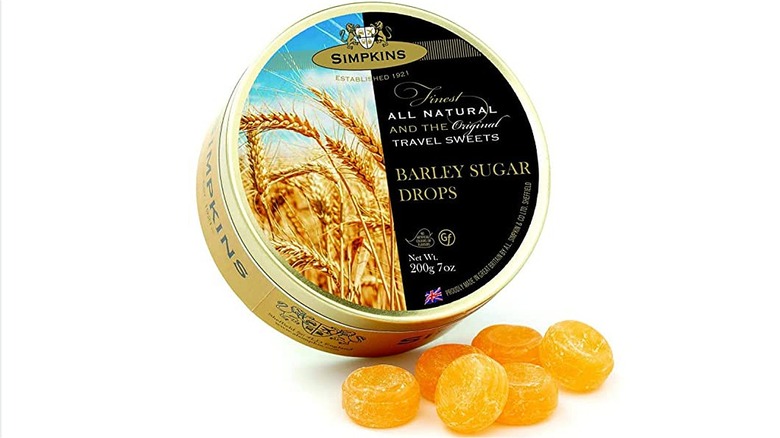

Over in the United Kingdom is Simpkins Barley Sugar out of Sheffield, which has specialized in travel-sized, candy containers since 1921. Their barley sugar drops are billed as the world's first travel sweets, designed to fit easily into a purse or trouser pocket. They are easily found online.

Barley sugar pops and candy toys, cleverly molded into floral or retro shapes, can be purchased at both OldTimeCandy.com and The Vintage Candy Shop. Each specializes in traditional, old-fashioned sweets.