How Fish Changed The Frozen Food Industry Forever

When you stop and think about it, frozen food is really quite a phenomenon. Many of us might take for granted the fact that several aisles of our grocery stores are filled with food that has been picked, caught or prepared, frozen, and packaged. It can arrive on our dinner plates after mere minutes of reheating in the oven or microwave. This influential industry, and the flash freezing process itself, can be traced back to one man's fateful trip to the Arctic and the method of food preservation he observed there.

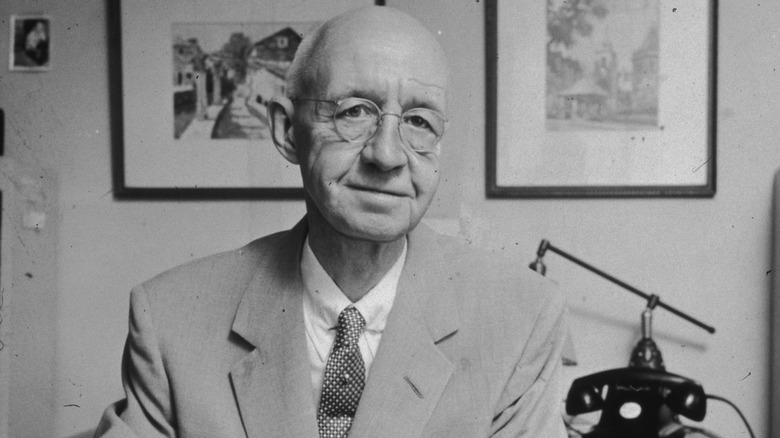

In the early 1900s, Clarence Birdseye, a biologist who quit college and began working as a naturalist for the U.S. government, was posted to the Arctic region of northern Canada (via Lemelson-MIT and the Birds Eye website). There, he was able to observe the native Inuit process of preserving fish. Utilizing the elements at their disposal — ice, wind, and temperature — the Inuit were able to instantaneously freeze their freshly caught fish. Upon further investigation, Birdseye discovered that there was virtually no difference in the quality of taste or texture between the frozen and fresh fish. What he did next would change the course of food history.

Flash freezing changed the food game

Commercially frozen food had existed for nearly 50 years by the time Birdseye started his company in the 1920s. However, History.com explains that because the available freezing process froze food very slowly, large ice crystals would form and "adversely affect the food's cellular structure." This caused a loss of flavor and increased the likelihood of spoilage, making frozen foods to be highly unpopular with the American public. Remembering his time in the Arctic, Clarence Birdseye developed a new way of freezing food on a commercial scale: flash-freezing.

Per the Library of Congress, Birdseye' developed two approaches. Under the more common method, foods that had already been packaged would be frozen under high pressure between two metal plates that had been chilled to minus-25 degrees Fahrenheit by evaporating ammonia. Lemelson-MIT describes the packaging as "waxed-cardboard cartons." A pack of meat measuring 2 inches thick took 90 minutes to freeze. Vegetables froze in 30 minutes. Ice crystals remained small, preventing damage to the cellular structure of the food.

Americans didn't really start buying frozen until WWII caused a canned goods shortage. Despite taking some time to catch on, Birdseye's innovations, which also included refrigerated trucks and freezers in grocery stores, helped make frozen foods a staple by the 1950s (via History.com). According to the American Frozen Food Institute, the frozen food industry employs over 67,000 workers in the U.S. alone and represents a $65 billion sales market. Not a bad legacy for a college drop-out.