The Process Of Nixtamalization, Explained

Nixtamalization, pronounced NEESH-ti-mal-i-za-shun, is the ancient process of soaking corn in an alkaline solution to soften the kernel's texture and improve its flavor. Originating centuries ago from Mesoamerica, this ingenious cooking method enabled corn to become the major staple food it is today, (via Eccentric Culinary).

Before modern chemistry enabled cooks to use things like cooking lye, indigenous people have been resourceful when nixtamalizing their corn. Ashes, specifically hardwood ashes, were traditionally used for nixtamalization — that which is further explained in the name. The word nixtamalization stems from the Aztec language Nahuatl where nextli means ashes and tamali means corn dough, reports CIMMYT. While you may enjoy tamales, tlacoyos, tortillas, or pupusas every day, you may not have realized the complex process that goes into making all of these corn dishes. We have created the complete guide to nixtamalization so all of your corn-y questions can be answered right here.

What is nixtamalization?

Learning about nixtamalization is a process, just like the actual process of cooking and soaking the corn kernels, so buckle up. Nixtamalization is a way to process food. While some of you may immediately think of chips or fast food when you hear processed food, processing food can mean anything from cutting fruit to soaking it in lye, as is done in the process of nixtamalization.

Once dried corn kernels are nixtamalized, they are ground into masa. From there, the possibilities are truly endless. The masa can be used to make many of our favorite corn dishes, or the masa can be dried into corn flour and stored as a pantry item to keep on-hand. For centuries, this ancient technique has served as a way to preserve corn products and ensure that they have a longer shelf life and stay fresh and nutritious, rather than stale and bland.

History of nixtamalization

Without nixtamalization, many of the world's communities that rely on corn, or maiz, as their staple crop and starch would face nutrient deficiencies. Nixtamalization changes the chemistry of corn, making it more nutrient-rich. Throughout history, this ensured that people who rely on corn as their staple crop don't face nutrient deficiencies, (via Science History Institute).

This ancient process dates back to 1200-1500 B.C., but it is difficult to pinpoint when exactly nixtamalization was first discovered. Nonetheless, it's well agreed upon that this process is at least 3,000 years old, (per Two Row Times), and was a fundamental aspect of Mesoamerican civilizations. Nixtamalization was first practiced in what is now known as Guatemala, where ancient equipment was uncovered and is believed to have been practiced by both the Mayans and Aztecs. Nixtamalization requires an alkaline solution. To achieve this, wood ashes were traditionally mixed with water, and today, this method is still practiced by many small-scale producers and families.

Considered more than a staple food, corn is sacred to the Mayan people. It is integral to the Mayan creation story because it is believed that all Mayans are descendants of the first human, who was made from maiz, or corn. This demonstrates how corn is much more than a food, it is a belief system and an essential aspect of Central and South American cultures. Therefore, the discovery of nixtamalization, a way to process corn and make it more nutrient-rich, was groundbreaking for the Mesoamericans, notes Eccentric Culinary.

The process

So now that you know what nixtamalization is, it is time to learn how it actually works. Traditional nixtamalization can be broken down into six main steps: washing, cooking, steeping, rinsing, milling, and cooking. These general steps are the secret to success in terms of nixtamalization, however, with any traditional cooking method, there are many variations in how nixtamalization is done depending on the family, corn, region, and resources. If not all of these steps are followed, then the kernels may not undergo the chemical and physical transformations that are necessary for making the perfect masa.

Did you know that every tortilla in every taco goes through a process similar to this? While today many industrial tortillas and masa mills take some shortcuts, the process is more or less the same and has been for centuries. Therefore, without these six essential steps, we would not have the delicious, tender, and deeply satisfying corn foods that we all love.

First you wash

The first step, washing, involves exactly what you think it does. The most essential component of anything made from corn is the quality of the corn itself. Therefore, to make the best masa, or corn dough, you must start with a type of corn that is actually fairly difficult to find in the U.S., dent corn. Dent corn, unlike sweet corn that is picked while still immature and therefore soft and sweet, is left to dry on the stalk until it is hard and starchy. Dent corn is perfect for nixtamalization because it is much starchier than sweet corn, giving masa body and flavor. Once the dent corn is washed and cleaned of any field or soil debris, it is time to cook it.

So, once you have found some starchy dent corn, you can begin your nixtamalization process. Washing off the kernels helps ensure that the whole process and your final masa are clean and purely flavored with the fragrant, nuttiness of the corn. Nixtamalization changes the flavor of corn so dramatically that you do not want to risk having any other bits of husk or dirt mixed in and ruining the taste.

Cooking the corn

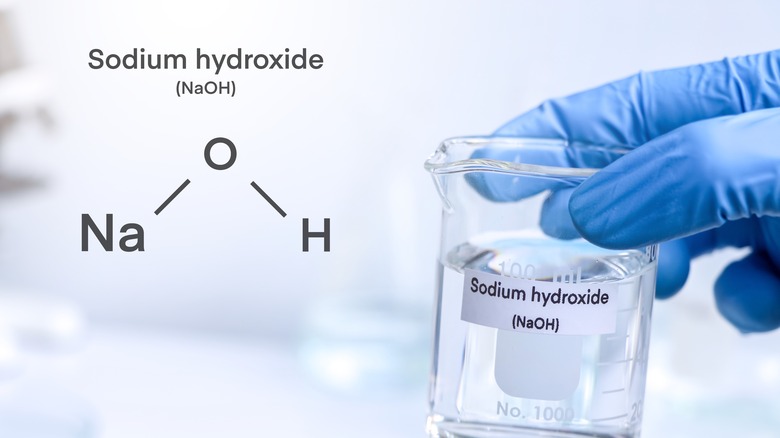

The cooking stage involves cooking the dent corn in an alkaline solution for 40 to 90 minutes, per the Mexicanist. In the past, this solution was created by mixing water with wood ashes. Today, the Navajo and Hopi nations are known to still nixtamalize their corn using traditional juniper tree ash to create the necessary alkaline slurry, says the Society of Ethnobiology. Other ways of nixtamalizing can be done by adding lye or calcium hydroxide to the cooking water.

For large-scale production, nixtamalization is sped up by the use of enzymes. This process, called enzymatic nixtamalization, involves soaking the corn in an alkaline solution that has an enzyme called proteas. The protease help dissolve the pericap, the top section of the corn, and the hull which is usually rinsed off during the final washing phase. This enzymatic method takes only a fraction of the time traditional nixtamalization does and produces less water waste. The downside of this modern method, aside from losing touch with a traditional and cultural cooking method, is that the final masa has a less aromatic, irresistible flavor, adds Eccentric Culinary.

The steeping stage

The next step to nixtamalization is the steeping stage. This stage, which can last anywhere from eight to 18 hours, (via the Mexicanist), is essential because it allows the kernels to soften, saturate, and undergo a chemical transformation in the alkaline solution. The steeping phase is actually quite simple. It purely involves having the kernels soak in their cooking liquid for a set amount of time, and having the foresight to plan ahead with your masa making. The kernels sit in their liquid and this is where the magic happens, which we will explain shortly in the chemistry explanation.

This long soaking period enables the hull of the kernel to loosen and eventually fall off during the washing process which comes next. During this phase, the kernels become quite bloated and take on the large, puffy look that is iconic of hominy. The alkaline solution, and the long soaking phase, work together to fully hydrate the kernels and make them even more supple before washing and milling.

Don't forget to rinse

The rinsing stage, which is the next step in the nixtamalization process, consists of rinsing off the soaked kernels to flush off the alkaline solution and get rid of the hull. This step also removes the pericap from the kernel which, when ground, results in a dough that is less fibrous and much smoother. The rinsing stage is important because it allows for the hull to be completely removed from the kernels, leaving them soft and slightly slimy.

Many of the hulls are so loose and already detached from the kernel that they can be removed just by rinsing the corn and agitating the water. However, there is always the occasional kernel, so if the hull does not rinse off some kernels, many people who nixtamalize their own corn will rub the kernels between their hands to further loosen the hulls, and facilitate the cleaning of each grain.

Grinding is next

Once the cooked corn is rinsed thoroughly and only the saturated kernels remain, it is known as nixtamal, (via Breadtopia). This nixtamal can be eaten as is in the form of hominy in dishes such as posole, or used to make masa. Masa, or dough, is the base of tortillas, tamales, pupusas, and many other corn-based foods. While masa is undeniably best when it is fresh from aromatic nixtamalized corn, it is also available in the form of masa harina, which is dried masa. We will explain the differences in just a moment, but for now, the milling process.

The nixtamalized corn is traditionally ground in a stone mill that crushes the kernels by rotating in a circle, squishing the kernels into a starchy mush, and eventually dough. It can also be made using a metate, a large stone basin with a rolling pin-shaped stone that crushes the kernels as the pin is pulled and pushed against the basin. Either of these methods, as well as more modern approaches such as a food processor, can be used to achieve the desired smooth and supple masa.

Cooking the nixtamal

Regardless of if you grind the nixtamal into masa, or keep the kernels whole, the final step in the nixtamalization process is making something delicious out of your hard work. You can use the whole kernels to make posole as we already suggested, or take the ground masa and create something beautiful. Fresh masa makes the most irresistibly fragrant and tender corn tortillas and can also be stuffed with a variety of fillings to make pupusas or gorditas.

If you are cooking your tortillas on a traditional comal, the thin pieces of bread will be ready in no time. If you do go through the labor-intensive process of nixtamalizing your own corn, make sure to appreciate how much the flavor and smell of the corn changes once it has been nixtamalized. While nixtamalized corn is renowned for its nutritional benefits, it is also highly prized for its richer, irresistible corn flavor that does not compare to a normal corn meal.

The chemistry of nixtamalization

So now that we have gone over the process of nixtamalization, it is time to delve deeper into the actual chemistry. The main player in the nixtamalizing process is lye, calcium hydroxide, or wood ashes. All of these additions achieve the same goal of making a very alkaline solution and therefore breaking down the hull and pericap of the corn. The power of nixtamalization does not stop there. On top of breaking down the tough hull, the alkaline solution also changes the chemistry of the kernel's starches and endosperm, resulting in kernels that are more flavorful and easier to grind into masa, (via Eccentric Culinary).

Nixtamalization also results in a partial gelatinization of the starch and a reduction in phytic acid which is a natural substance that can inhibit the uptake of some essential nutrients, (per CIMMYT). The benefits of nixtamalization on the flavor, texture, and nutritional content of corn make it a miracle process that transformed the world's populations and diets.

Masa harina

You may have heard of masa harina, and may now be wondering how masa harina differs from fresh masa and masa made from nixtamal. Fresh masa is made from fresh nixtamal, which we just learned about, while masa harina is the dry version of this. Masa harina is made from fresh masa that is then dehydrated into a powder and packaged as a shelf-stable product. This technique was revolutionary for the food industry when it was developed in the 1980s because it allowed many home cooks and restaurants to have fresh corn tortillas without going through the process of nixtamalizing their own corn, (via GRUMA).

However, new discoveries like this always come with downsides. It should be no surprise that one of the main places masa harina falls short, compared to fresh masa, is with flavor. While masa harina can be rehydrated into a nice corn dough, it is widely agreed upon that the flavor does not compare to the rich nuttiness of fresh masa. Moreover, having widely available masa harina has contributed to this traditional food preparation method being pushed aside for convenience and efficiency.

Masa harina vs. masarepa vs. cornmeal

Masa harina, as we've learned, is made from nixtamalized corn that was then ground into masa and dehydrated into flour. Comparing masa harina to masarepa and cornmeal or polenta is where it gets interesting. Masarepa, the flour used to make arepas, a staple corn dish in Venezuela and Colombia, is made from corn just as masa harina is. However, the difference between masa harina and masarepa is that masarepa is not nixtamalized, meaning that the raw kernels are milled without being soaked in an alkaline solution. This results in a somewhat tougher finished product that has a less intense corn flavor.

Finally, cornmeal. Cornmeal or polenta, a popular grain used to make cornbread or grits is also a corn product that is not nixtamalized. Unlike masarepa though, cornmeal and cornflour are often ground much coarser resulting in the crumbly, gritty texture that we love. Nonetheless, cornmeal and polenta have an interesting history.

When the Spanish brought corn back to Europe from the Americas, they did not bring back the technique of nixtamalization. Therefore, when many cultures in the south of Spain, France, and across Italy became dependent on this roughly milled corn as their staple crop, turning it into what is now known as polenta, it was detrimental to their health. Since nixtamalization was not performed in these regions, the corn did not undergo the chemical transformations that make it more nutrient-rich, therefore resulting in large nutrient deficiencies across these regions, (via Eccentric Culinary).

Nutrition of nixtamalization

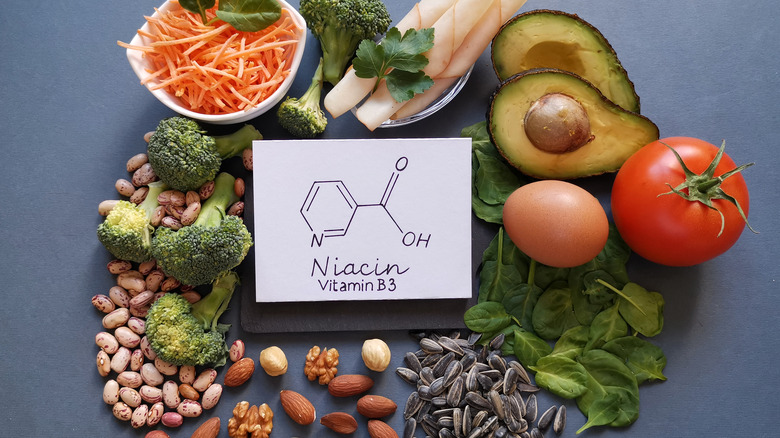

Speaking of nutrient deficiencies, let's learn how nixtamalization benefits us nutritionally. When the corn is introduced to the alkaline solution, and then soaked for a period of time, all of the aforementioned chemical processes take place. But why are these important? Well, first off, and maybe most importantly, the alkaline solution helps release niacin from the kernel. This suddenly makes corn a viable source of niacin and prevents individuals from suffering from pellagra, a niacin deficiency, (via Eccentric Culinary).

Eating non-nixtamalized corn doesn't provide nearly as much niacin to the body, and can often lead to death if left untreated. This is what happened to many of the communities in southern Europe who began to rely on raw corn as their staple starch, notes Eccentric Culinary.

Nixtamalizing corn also has other nutritional benefits such as producing certain amino acids which help break down proteins, specifically those found in beans, (per Eccentric Culinary). Additionally, nixtamalization contributes to the decline in phytic acid which usually acts as a nutrient uptake inhibitor. Therefore, after nixtamalization, the body is more readily able to absorb nutrients such as iron, adds CIMMYT. Nixtamalization also acts as a way to clean the corn and reduce the presence of microbiological activity and mycotoxins that commonly grow on corn. All of these nutritional benefits make it obvious that nixtamalization is a vital process that not only improves the flavor and texture of corn-based foods but also provides the body with sustaining nourishment.

Other uses

Using an alkaline solution to change the flavor and texture of foods is not as rare as you may think. Pretzels, bagels, ramen, and many other foods are cooked in lye. Therefore, it is no surprise that other foods, specifically fruits and vegetables, can be nixtamalized as well. While some chefs may be nixtamalizing their produce to improve the flavor, others do it for the texture. In Thailand, this is a common practice that most often involves bananas and red lime paste. To make classic street-vendor fried bananas, you need ultra-ripe bananas. But, as any banana-lover knows, the riper the banana the softer it is.

Therefore, in order to achieve a crispy, sweet, yet firm, fried banana, it is common for very ripe bananas to be soaked in a mixture of red lime. The lime helps gelatinize the fruit so that even when cooked, the bananas can maintain their structure and form the most irresistibly crunchy skin.