11 Ways Distilleries Are Becoming More Sustainable, According To Industry Experts

All good things have a cost, and that includes our favorite spirits. Unfortunately, when it comes to alcohol? Our planet may pay the biggest price of all. Between procuring the necessary ingredients and materials, production, and transportation, distilleries tend to create a hefty carbon footprint. In 2012, a Beverage Industry Environmental Roundtable (BIER) study found that producing a single 750-milliliter bottle created more than 6 pounds of CO2 equivalents on average (or greenhouse gases capable of contributing to global warming).

Now, while many distilleries face similar sustainability challenges found in other industries, there's a growing trend in the spirits industry to embrace production methods and processes that reduce waste, pollution, and overall carbon emissions. This includes sustainable spirits brands sold in stores across the U.S., as well as a general shift in business practices and production techniques designed to lower the emission of CO2 equivalents.

To gain insight into what distilleries are doing to become more sustainable and less environmentally detrimental, we turned to industry experts: Cameron Mackenzie, the co-founder and head distiller of Australian distillery Four Pillars Gin (where I previously worked); Allison Evanow, the founder and CEO of Square One Organic Spirits; and the brand director of Tequila Cazadores, Jay Needham. After speaking with each industry insider and researching the current industry landscape, we can paint a clearer picture of the positive leaps taken by distilleries to improve sustainability. Here are 11 ways distilleries are becoming more sustainable, according to experts.

Reusing hot wastewater to save energy and water

Every liter of alcohol produced creates 12 liters of wastewater – which distilleries need to either dispose of or repurpose. Of course, beyond any concerns surrounding excess water consumption, this wastewater can be a toxic pollutant. In other words, what distilleries choose to do with this water can have a drastic environmental impact. Thankfully, many distilleries have developed ways to recycle this water while adopting energy-efficient cooling techniques.

Four Pillars head distiller Cameron Mackenzie told us the distillery uses an innovative "veil" made of copper that surrounds the facility as a fence-radiator-hybrid. This allows the distillery to cool the water without additional energy usage, and then reuse the water in its condensers. "Without this," Mackenzie said, "we would drop approximately 60k – 80k liters of fresh water down the drain each day." Reclaiming the heat from hot waste water also provides a way to heat the distillery's tasting room during colder months.

Another distillery notable for its wastewater repurposing is Marble Distilling. Marble employs a similar tactic as Four Pillars called WETS (water energy thermal system) to store hot wastewater for later usage, which is used as a heat source for the facility. Four Pillars and Marble aren't the only distilleries dedicated to reducing wastewater disposal, though. More and more distilleries have started implementing systems such as these, including popular Islay scotch producer Bruichladdich Distillery.

Sourcing chemical-free ingredients

While some confusion exists surrounding the difference between natural and organic foods, it's common practice for many to seek whole, unadulterated, additive-free groceries for personal consumption. It stands to reason, then, this same approach should apply to the ingredients that go into our spirits. Now, for bigger distilleries, sourcing ingredients in large quantities can make it harder (if not impossible) to work closely with local farmers. However, seeking out certified suppliers is still feasible and can be a great strategy.

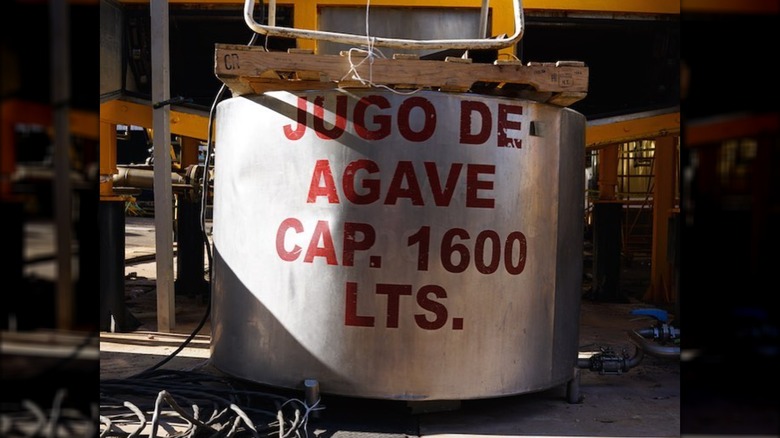

Tequila Cazadores, for instance, pays close attention to how its agave is harvested. As the company's brand director Jay Needham told Tasting Table, "We need to make sure their agave is grown in a sustainable way in order not to damage the soil nor the aquifer system." Another distillery known to use ingredients free of harmful chemicals and synthetic fertilizers is Bainbridge Organic Distillers, which reduces the risk of harmful pollutants entering water sources and soils near the distillery.

Whether a distillery sources grains, agave, botanicals, or fruit for its production process, it can make sustainable decisions that support the environment — particularly if it hopes for liquors like American whiskey to have a more sustainable future. Plus, as demonstrated by sustainable distillery Frey Ranch debuting a single-malt smoked American whiskey in 2023 made with ingredients wholly free of harmful chemicals? It's more than possible for sustainability and success to go hand in hand.

Using renewable energy sources

Not only is distilling water-intensive, but it requires exorbitant amounts of energy. Consequently, distilleries have important decisions to make regarding which energy sources to use — like whether or not to utilize something sustainable. One way for a distillery to ensure it uses sustainable sources is by partnering with like-minded businesses for its energy production processes, as is the case with Square One Organic Spirits.

"Our distillery partner has aligned with Rocky Mountain Wind Power to source a significant amount of their power from wind farms nearby," Square One CEO Allison Evanow explained to Tasting Table. More than that, wind is responsible for "40% of their energy use, which in distillation is quite high." Square One Organic Spirits isn't the only distillery that demonstrates the immense power of choice when it comes to sustainable practices, though.

Tequila Cazadores powers an astounding 99% of its distillery with renewable energy. Another aptly named distillery, Solar Spirits, aims for complete solar power (and currently uses solar tubes to power its mash process). Other successful distilleries around the globe have begun utilizing the sun's energy in recent years. The carbon-negative English distillery Two Drifters took home the 2023 IWSC Green Spirit Initiative Trophy – one of the industry's top accolades for sustainability — thanks to its use of 100% renewable energy that even powers a fleet of electric vehicles.

Reducing carbon emissions with local ingredients and packaging

In recent years, there's been a lot of hype surrounding the environmental cost of transportation — specifically, how much this contributes to CO2 emissions. But this doesn't merely relate to personal car rides or vacation flights. In fact, one of the biggest reasons for distilleries' immense carbon footprint is the transportation required to source ingredients for production, as well as materials needed for packaging (such as glass).

Now, to reduce carbon emissions related to transportation, some distilleries produce ingredients and materials internally. For example, the Scottish gin producer Arbike Distillery grows its own juniper to cut back on the impact of shipping. Meanwhile, Square One Organic Spirits only sources ingredients grown within 750 miles of its partner distillery in Idaho — a far shorter distance compared to products purchased across the country or imported from the U.K.

As Square One Organic Spirits CEO Allison Evanow explained, "Working with farms within a limited radius to source grain reduces the overall carbon footprint of shipping and supports local farmers." Perhaps inspired by its fellow distilleries, famed Scottish distillery Bruichladdich has plans to move its malting operations onto its native Islay and away from the Scottish mainland — thus reducing hauling distances and any related CO2 emissions.

Four Pillars pipes gin directly into the bar to reduce glass waste

Sustainability isn't a sprint, but it's not exactly a marathon, either — it's more like a relay race. After all, it's fine and dandy to optimize sustainability during the production process, but you can't win a race if the baton is dropped during the next stage. If a distillery thinks through every stage of a product's journey from raw ingredients to the customer's lips, though, it can keep its sustainability ambitions on track — as evidenced by Four Pillars Gin.

For starters, Four Pillars Gin has removed glass use from a critical — but often overlooked — part of its on-site service. Rather than supply the distillery bar with glass bottles filled with its gin, copper pipes deliver the product directly to the bar. This means unnecessary glass use is avoided by eliminating the need to fill (and then discard) glass bottles used at the same location.

At Four Pillars, refillable bottles are displayed behind the bar atop the pipes to keep the product visible, but these bottles are used over and over again. Furthermore, gin's greatest friend, tonic, is keg-supplied to reduce glass usage at that stage, too. This means guests can enjoy a classic gin and tonic sans environmental guilt when visiting the distillery.

Incorporating recycled and recyclable materials in packaging

Food has had a bit of a head start when it comes to sustainability. Consequently, there's plenty of available evidence to demonstrate that sustainability-motivated business practices are possible when it comes to packaging — like the fact that packaged meals aren't always worse for the environment. Now, according to a 2012 BIER study, a glass bottle was responsible for up to 20% of an alcoholic product's carbon footprint. Since that time, though, numerous distilleries have focused on cuts, swaps, and complete re-imaginings of packaging techniques to reduce the negative environmental impact.

For instance, Bruichladdich claims to have cut 65% of its packaging's carbon emissions by redesigning its bottle. The refurbished bottle is made with 60% recycled glass and is 32% lighter than its previous bottle. Meanwhile, the English distillery Gin Kitchen has done away with glass altogether and opts for eye-catching white porcelain bottles with biodegradable wood stoppers instead. Since this makes the bottle reusable, the distillery offers a discount on refills for returning customers. Gin Kitchen also uses recyclable cardboard boxes with paper-based tape to further reduce its environmental impact.

Some distilleries have altered the composition of labels, as well. Square One Organic Spirits uses FSC (Forest Stewardship Council) certified papers for its labels to verify the viability for recycling. Additionally, the rum distillery Two Drifters uses labels made almost entirely from sugarcane fibre that's been repurposed from waste.

Repurposing used ingredients

Distilling spirits creates many byproducts — some more useful than others. Now, when the grains used in the spirit distillation process have had their sugars fully extracted, it becomes a waste product. But in the eternal quest to balance the scales of environmental impact, some distilleries have gotten creative with these waste products and turned them into something valuable. Marble Distilling sends this spent grain to local farmers for feed to ensure this particular byproduct's destiny isn't a nearby landfill.

The process of distilling gin results in spent botanicals, as well. Distilleries like Four Pillars Gin don't toss the no-longer-fresh oranges out after the distillation process, but use them to create a gin-enhanced marmalade. The distillery sells this as part of its "Made from Gin" program and also offers salt and chocolate products made with these dried, spent botanicals. Additionally, many distilleries made concerted efforts to create alcohol-based hand sanitizers during the COVID-19 pandemic – and distilleries such as Gin Kitchen continue to do so to reduce pesky toxic alcohol waste. After all, while this waste can be bad news for the environment, it's also bad news for bacteria and viruses when turned into sanitizer.

Furthermore, Tequila Cazadores uses its byproducts to help its agave farmers, and brand director Jay Needham described this process to Tasting Table. "After the distillation process, treated bioproduct is used as organic fertilizer for the agave fields which means we send zero waste to landfills from this process."

Setting public sustainability goals

The primary motivation for distilleries to become more sustainable isn't necessarily a desire to look good (though that's always a possibility!). Still, a business can help cement these practices by publicly declaring its sustainability goals. Eco buzzwords can be effective, but to use another cliché: actions speak louder than words. When a distillery is transparent about its sustainability goals, metrics, and achievements, it helps conscientious consumers find products that are genuinely better for the planet — which, in turn, promotes sustainability across the industry.

One distillery that offers total transparency is Two Drifters. Its entire sustainability report is available online and provides detailed insight into its practices for interested customers. This is how a distillery puts its money where its mouth is and shows it takes sustainability seriously. Sharing sustainability timelines is also important for distilleries, as it allows these businesses to describe an action plan and garner support when pursuing more environmentally friendly processes.

For example, Bruichladdich proudly shares its goal of completely decarbonizing its production alongside actionable steps to reduce waste, emissions, and local environmental impact. Tequila Cazadores has also shared its goal of ensuring all blue weber agave it uses is certified as sourced sustainably by 2025. Simply put, sharing sustainability goals creates accountability for distilleries and generates consumer passion for products that meet their standards.

Creating double-strength spirits to reduce energy use

Taking steps before and after distillation can determine how sustainable a spirit is to produce. Yet the distillation process itself offers opportunities to reduce energy consumption, as well. Using a pot still is a common practice when distilling many types of spirits, including whiskey, tequila, and rum. When used for the second distillation of gin, however, there's a tactic that helps distillers increase sustainability.

In the typical pot still gin distillation process, a neutral base spirit of about 50% alcohol (the remainder being water) is boiled with botanicals until the flavored distillate passes through the still — arriving at a drastically higher alcohol volume. In a traditional "one shot" process, the amount of botanicals that go into the pot and the distillate's resulting strength are such that the result is what goes into the bottle after dilution. With a "double-shot" process, the amount of botanicals is doubled. This results in a spirit that's twice as intensely flavored before more neutral alcohol is blended in to bring the solution back to the ratio that matches the gin's recipe.

This method greatly reduces the energy used per bottle, which is why Four Pillars Gin has started using it. After all, "the gin will remain the same but we will potentially halve the energy inputs per bottle," as Four Pillars head distiller Cameron Mackenzie told us. "It's a far more responsible way to distill."

Cazadores uses a biomass boiler to fuel its process

As previously noted, one way to reduce emissions during the distillation process is to get creative with the fuel that powers your stills. While some distilleries have achieved or approached carbon neutrality by choosing renewable energy suppliers, Tequila Cazadores actually supplies its own renewable energy source.

Brand director Jay Needham explained the distillery's ingenious process to Tasting Table. "At our distillery, the leftover agave fibers that do not contain sugar are converted into biofuel which powers the biomass boilers used during the extraction, cooking, and distillation processes." This biomass boiler can reduce greenhouse emissions by 80% when compared to the emissions produced by traditional fossil fuels like diesel and gasoline. Even the ashes produced by the boiler serve a purpose and are used as a potent fertilizer in compost.

Around 60% of the biomass that fuels the distillery's boiler comes from spent agave fibers. The rest is comprised of waste wood, biomass briquettes, and other combustible yet renewable waste products like tree cuttings and coconut shells. With thousands of tons of biowaste repurposed as fuel by Tequila Cazadores every year, the distillery is fully committed to sustainability — and could teach a thing or two to other distilleries.

Embracing automation to increase energy and resource efficiency

There's no doubt that using manual processes throughout the production and distillation of alcohol can add a desirable human element. Unfortunately, this also comes with the inherent limitations of human error and labor, which is why at least one distillery has turned to automation to improve efficiency and lessen its environmental impact.

Marble Distilling claims to have improved its efficiency by 75% since the installation of Desigo Automation technology created through a partnership with Siemens. The Desigo Control Point hasn't just reduced the need for on-site labor, though, as the Siemens-designed actuators and valves give the facility tighter control over its distilling process from start to finish.

Combined with the distillery's WETS water reuse system, the new technology even allows the distillation process to run overnight without staff — cutting down on the overall resources required to produce each bottle compared to standard manual practices. Given the success of Marble Distilling's technological approach towards sustainability, then, it's likely only a matter of time before other distilleries follow suit.